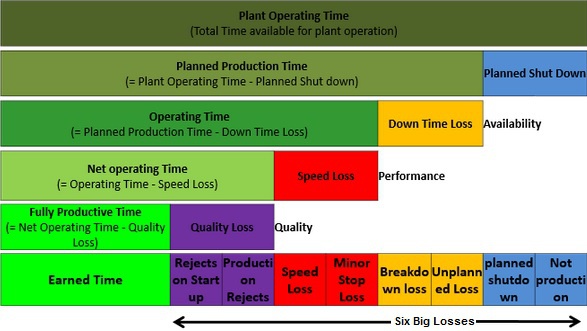

OEE Factors

• Productivity losses in manufacturing plants are due to three factors: Availability, Performance and Quality.

• Availability considers downtime loss: Equipment stops, change over time.

•Performance considers speed loss: Causes preventing process to operate at nominal speed.

• Quality considers quality loss: Loss for rejected produced pieces.

• Availability considers downtime loss: Equipment stops, change over time.

•Performance considers speed loss: Causes preventing process to operate at nominal speed.

• Quality considers quality loss: Loss for rejected produced pieces.

Why OEE?

•If you are looking for ways to:

• Identify inneficiencies in your machines and production lines.

• Standarize the way you measure equipment efficiency.

• Take advantage of the hidden capacity you may have available in your equipment.

• Identify inneficiencies in your machines and production lines.

• Standarize the way you measure equipment efficiency.

• Take advantage of the hidden capacity you may have available in your equipment.

Six Big Losses

1. Breakdowns> Down Time: Failures, Breakdowns, Unplanned Maintenance.

2. Setup and Adjustments> Down Time: Changeover, Setup and Adjustments, Shortages.

3. Small Stops> Speed: Machine Jam, Product Flow Blocked, Checking.

4. Reduced Speed> Speed: Running Under Capacity, Equipment Wear, Machine or Operation Inefficiency.

5. Startup Rejects> Quality: Scrap, Rework, Assembly Errors.

6. Production Rejects> Quality: Scrap, Rework, Assembly Errors.

2. Setup and Adjustments> Down Time: Changeover, Setup and Adjustments, Shortages.

3. Small Stops> Speed: Machine Jam, Product Flow Blocked, Checking.

4. Reduced Speed> Speed: Running Under Capacity, Equipment Wear, Machine or Operation Inefficiency.

5. Startup Rejects> Quality: Scrap, Rework, Assembly Errors.

6. Production Rejects> Quality: Scrap, Rework, Assembly Errors.

What is OEE?

• OEE Stands for Overall Equipment Efectiveness.

• OEE is a standarized, systematic and consistent way to measure industrial equipment efficiency.